Ad The 1 Choice For Metal Builders When It Comes To Roll Forming. Should you be a colorful Woman then you can take up brighter color tones on your nails if you like delicate issues so of course your temper will pick up on nail paints which have been a bit dull and fewer flashy.

4 Roll Plate Bending Machine Hr4wr

But Did You Check eBay.

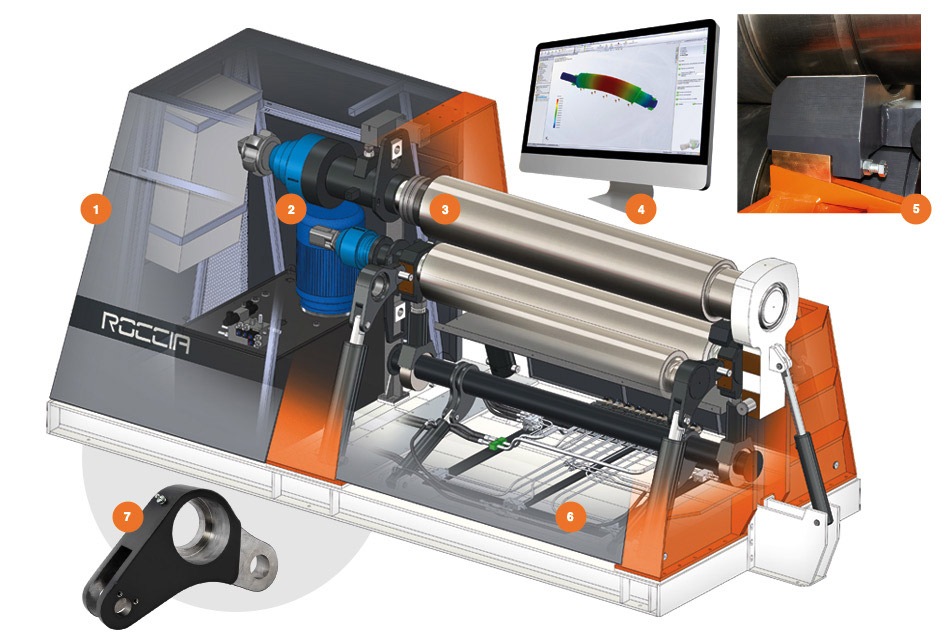

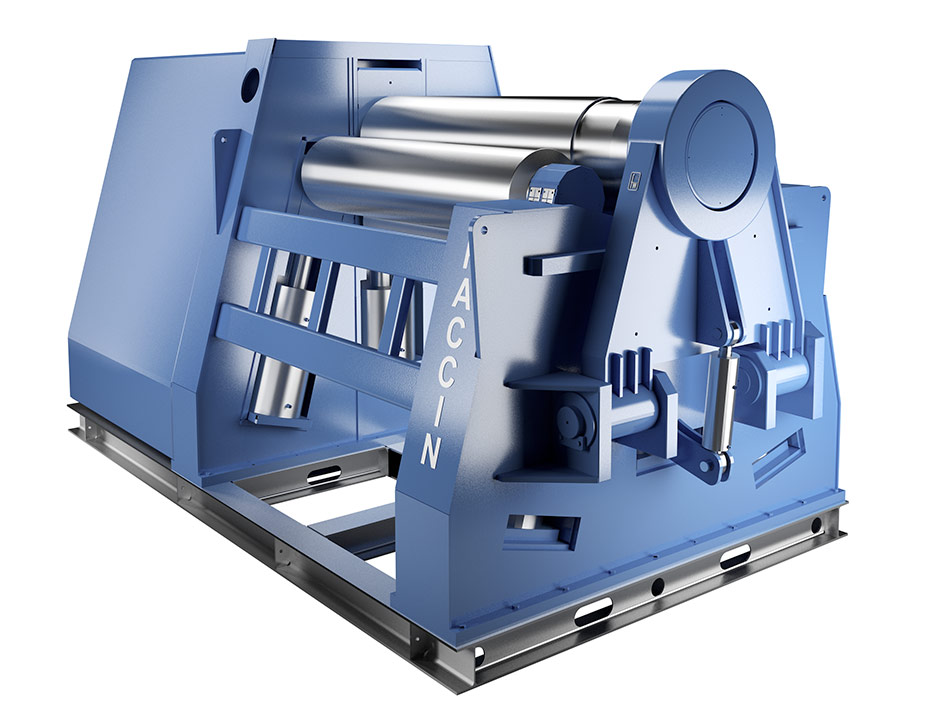

. The two lower rolls can be adjusted individually of each other with infinitely variable adjustment speeds in a curved path around a common center. The same design works with angle rolls also. Plate bending machines or also round bending machines are used for bending sheet metal webs and are divided into different types according to the number of rollers installed the 4-roller round bending machine is one of the designs.

Ferrules in full circle or varying radiuses can be done easily. Bending becomes childs play. From Plasma Cutters To Press Brakes We Have New Used Machinery For All Of Your Needs.

4 Roller Plate Rolling Machine Model. Request A Quote Today. The fastest and most accurate bends are made by four roll machines.

4 Roll Plate Bending Machine Jmt Usa Plate Bending Machines The inner radius of the bend formed in the metal is determined not by the radius of the upper tool but by the lower die. Modern and functional design. 4 Roller Plate Rolling Machine.

The bending power of a 4-roll machine is exerted to the plate by two side rolls. A winning combination for those looking for. Depending on the chassis design the weight reduction potential may be even higher up to 50.

These criteria were decisive in the development of the machine. Modern appearance safe operation and at the same time optimal operability. 4 Roll Plate Bending Machine Design.

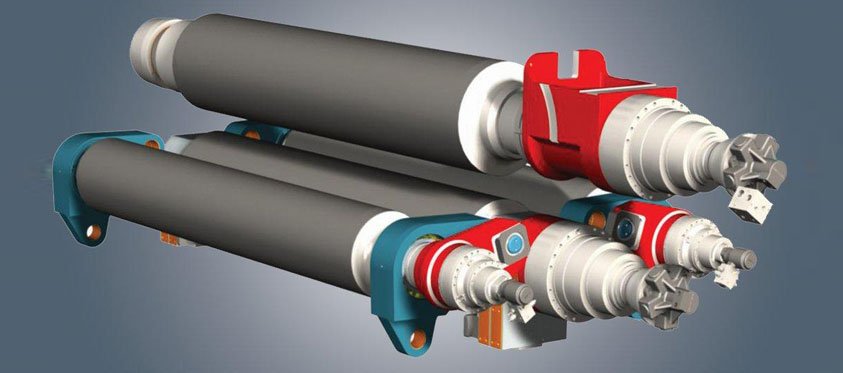

The main features of our VBH rolls are the greater lower roll pinching force for short flat ends and optimum pre-bending and the higher driving torque for single pass process to boost productivity. 4 Roll Plate Bending Machine. BENEFITS OF 4-ROLL PLATE BENDING MACHINES Four roll plate rolls are more precise productive versatile faster safer and easier to operate than three roll machines.

4 roll plate bending machine design Nail artwork conjures up All people. Show LEMAS 4 Roll Plate Roll. The drive was still mechanical using cardan shafts to transmit torque and rotation which cannot be linked up directly because of the movement of the two driven rolls.

Double-pinch pyramid design enabling pre-bend at both ends of the plate. 60 x 14 LEMAS C 4-roll double pinch plate bending roll 480 3 phase 3450 x 1150 x 1200. 4 Roll Plate Roller Plate Rolling Machine is suitable for the bending forming work of sheet metal.

56 Defi ne design synthesis. The quality of a profile rolled on this plate roll machine will be the same to ones rolled on 4-roll double pinch or 3-roll initial-pinch machines. VBH 4-roll plate bending rolls.

Check Out Top Brands On eBay. The four rollers consist of an upper and lower roller and two side rollers. They are less dependent on operator competence.

Modern Novel Design Small Roll Stainless Plate Machine 6mm Thickness Plate Rolling Machine With Cone Roll Find Complete Details about Modern Novel Design Small Roll Stainless Plate Machine 6mm Thickness Plate Rolling Machine With Cone Roll6mm Steel Plate Rolling MachineHydraulic 4 Rolls Conical Plate Bending MachinePlate Iron Sheet Rolling Bending. 2016 Notable Features Heavy duty gear-motor drives top and bottom pinch rolls Powered Bending Roll Adjustment and Manual Precision Pinch Roll Adjustment Pedestal Control Quick Ro. The P value from table multiply by 2.

It can roll round curved and tapered workpieces within. Ad Mac-Tech Offers Top Quality Metal Fabrication Equipment Repairs. They are ideal for bending plates up to 6 thick.

EVO 4-roll plate bending machine. The 4 roll double pinch plate bending machine design enabled the plate to be pre-bent in the rolls and having the second outer roll it was possible to pre-bend both ends of the plate without the need. W12-162000 bending thickness 16mm pre-bending 13mm width effective 2100mm top roller 270mm PLC control rolls harden short flat ends different shapes smaller diameter top crane side supports and cone bending optional.

Unlike other solutions on the Market DAVI exclusive design provisions a planetary actuation of the side rolls whereas rather than being guided up and down the mechanism rotates around a pivoting point. The VBH is the best machine for both cylindrical and conical bending. INDUSTRIAL 6 x 516 INITIAL PINCH PLATE ROLL.

PLC control for rolling production. Ad Free Shipping Available On Many Items. Hydraulic 4 roll plate bending machine with double pre-bending Useful length from 3 to 20 Thickness from 18 up to 5 Fully hydraulic movement of rolls and drop end CNC machined main frame components Oversized hydraulic cylinders to reduce working pressure and ultimately increase machine longevity and overall durability.

4 Roll Plate Bending Machine Hr4wr

4 Roll Plate Bending Machine Mg Plate Rolling Machines Mg Srl

Plate Bending 4rolls Hydraulic Plate Bending Machine 4r Hss 4 Roll Plate Bending Machine

4 Plate Bending Machine With Planetary Swinging Arms 4hep Faccin

4 Roller Plate Bending Machine Structure And Precautions Machinemfg

4 Roll Plate Bending Machine Jmt Usa Plate Bending Machines

Load Analysis And Drive Power Calculation Of Four Roll Bending Machine Plate Roller

0 comments

Post a Comment